GCSE Business Studies 0450

Business Studies – Operations Management

- Methods of production.

- Understand the difference between job, batch and flow production

- The importance of quality – Quality Control, Quality Assurance and TQM.

- Economies and Diseconomies of scale.

Methods of Production

Factors companies have to consider when choosing a production method include:

1. Nature of the product, unique products or services are required and need to be specifically tailored to the needs of the customer, job production will be used. If the product can be mass-produced using automation then flow production will be used. If time or location is a restriction, then batch may be better

3. Nature of Demand if there is a large and steady demand for a product, it becomes economic to set up flow production to continuously produce that product

2. The size of the market indicates whether products can be sold in large quantities. The product will be made in quantities to meet orders. Small or niche markets will usually be served by job or batch production. Large international markets are served using flow production.

4. Size of the Business if the business is small and does not have access to large amounts of capital for flow production. Only large businesses can operate on this scale, small ones are likely to use Job or Batch production.

The method of production a business uses depends on the scale of the production, the type of product and available capital or resources. It’s important to understand the difference between each method of production and recommend an appropriate method of production.

Job Production

Batch Production

Flow production

Cell Production

Batch production is used when a small number of identical products are made at the same time. Each batch goes through one stage of the production process before moving to the next stage. A good example is making batches of shirts for medium, large and small. Bakeries will also bake in batches of twelve, twenty-four or more depending on the oven size and product.

. .

.

Exam Tip

It’s important to remember that flow production can enable a business to gain economies of scale. Job production is less likely to help a business achieve economies of scale. If you are unsure how economies of scale work, take a look at the topic.

Involves making individual products from start to finish. Each product is different and meets the unique requirements of the customer. Job production is often used by hairdressers, wedding dresses or wedding cakes.

Because the product is unique and bespoke the business can often charge higher prices as the product meets customer specifications.

Job production results in high-quality products as each product is made by skilled employees one at a time.

- Job Production can be expensive as workers tend to have higher skills and therefore higher wages.

- Time-consuming as completion takes longer due to greater attention to detail and higher quality products. As products are made for a specific purpose replacements can be difficult to source.

Job production is where one item is made at a time, usually by skilled employees. Job production is chosen when the product needs to be made to meet the individual needs of a customer.

Flow production is where products are produced continuously using a production line. Partly finished products (goods) flow along the assembly

line with parts being added throughout the process. Think golf balls, cars or Coca-Cola.

The advantage of flow production is that a high number of products can be made at a lower cost. Because production can continue 24/7 and businesses can benefit from economies of scale. This means that the average cost per unit can be lowered.

.

The importance of Kaizen

Kaizen means continuous improvement and is a policy of constantly introducing small incremental changes in a business to improve quality and efficiency. Kaizen assumes that employees are the best people to identify room for improvement since they always see the processes in action.

Improvements are based on many, small incremental changes rather than large radical changes. Ideas come from the workers themselves. Employees should continually seek ways to improve their performance. Kaizen encourages workers to take ownership of their work and can help reinforce teamwork, thereby improving worker motivation.

Definition of Kaizen

Kaizen is the continuous incremental improvement of an activity to eliminate waste.

Quality

Imagine going to the shops and buying trainers, when you get home and find it has a tear in it. You would not be a happy customer and the business could get a bad reputation if this happened often as a result the business will lose sales. If quality is not maintained, the business will lose customers, incur additional costs, and damage its reputation.

Quality assurance ensures checking for quality standards throughout the production process, whether it is the production of a product or service.

Quality control

Quality control is considered the traditional way of managing quality. Quality control is carried out by checking and reviewing work that has been completed.

Quality control

Quality control is mainly about detecting faulty output after the product has been made. Quality control can also be a costly process if faults are only detected after making a product the business could end up increasing waste

- Inspection

- Testing

- Sampling

Total Quality Management (TQM) is the continuous improvement of products by focusing on quality at each stage of production. This includes making sure to use quality supplies. With TQM quality is at the heart of everything the business does.

Advantages of quality

- Establishes a good brand image

- Gain a competitive advantage

- Builds brand loyalty

- Will maintain a good reputation

- Will help increase sales (market share)

- Attract new customers

CAD stands for Computer Aided Design software that draws products allowing them to be designed more quickly. Is used to design new products or adapt existing ones, specifically technical drawing.

CAM stands for Computer-Aided Manufactureing where computers monitor the production process. For example, car plants will be controlled from an office, controlling multiple processes, spraying, assembling and welding.

Economies of scale

The five factors that can lead to Economies of Scale are Purchasing economies when businesses buy large quantities of supply resulting in discounts for buying in bulk. Marketing economies are when a business can buy advertisements in large quantities. Financial economies allow large businesses to raise capital at lower interest rates. Bank managers consider lending to a large business less risky than lending to a smaller one. Managerial economies enable large businesses to have specialist managers increasing efficiency and reducing their average costs. Technical economies are when a business can use the best technology and capital-intensive methods of production.

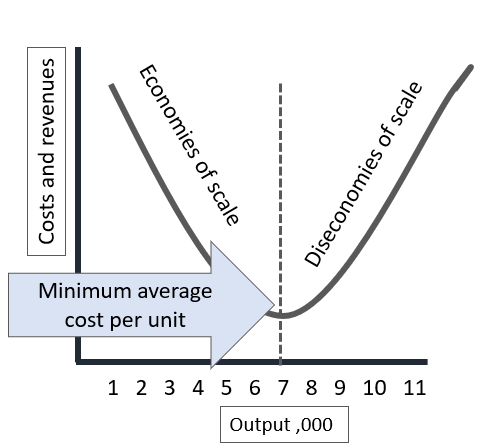

Economies of Scale are the factors that lead to a reduction in average cost per unit as a business increases in size.

Diseconomies of Scale are factors that lead to an increase in average costs as a business grows beyond a certain size.

Exam Tip

Economies of scale result in lower average cost per unit, not total costs. A large business is likely to have higher costs than a small business but lower average costs per unit.

Diseconomies of scale

Diseconomies of scale occur when a business becomes less efficient due to its scale leading to higher average costs.

Poor Communication – The larger the company the more difficult it is to send and receive information, and this means mistakes can occur which leads to lower efficiency and higher average costs.

Low morale – Large companies can employ thousands of employees. Employees may feel unimportant and not valued. In smaller businesses, it is possible to establish relationships between employees and management. The lack of employee relationships can lead to low morale and low efficiency increasing average costs.

Slow decision-making – It takes longer for decisions to be made in large companies

GCSE Business Studies Operations Management Exam Practice

GCSE Business Studies Revision Videos

Business Activity

Coming soon…

Types of business

Coming soon…

Exam Practice for Paper One

Coming soon…

Access additional Business Studies resources

Complete our contact form and let us know what topics you would like to improve.